At Douglas Equipment, we specialize in material handling equipment and casters. We keep tens of thousands of items in stock, ready for immediate shipment. We also work with all of the major equipment manufacturers and can quickly locate any items we do not stock.

At Douglas Equipment, we specialize in material handling equipment and casters. We keep tens of thousands of items in stock, ready for immediate shipment. We also work with all of the major equipment manufacturers and can quickly locate any items we do not stock.

One of the companies whose products we distribute is the Morse Manufacturing Company, founded in 1923. Morse is focused on providing equipment for every aspect of operations involving drums that may contain various materials. Morse makes equipment for lifting drums, transporting drums, tilting drums, rolling drums to mix the contents inside, and more. Moving fully loaded drums around industrial facilities can be heavy, dangerous work. Morse is committed to making equipment that eases the burden of this labor, and protects the safety of all of those who move and work with heavy drums.

Morse makes every item you may need for operations that involve drums, including smaller items like drum faucets. With Morse’s drum faucets (also known as drum spigots), you can start the flow and dispense liquid from your drum, adjust the flow while the drum is emptying, or stop the flow at any time. The faucets fit the standard two inch and 3/4 inch bung sizes commonly found on 30 and 55 gallon drums. Morse makes faucets compatible with thick, viscous liquids, or with thin liquids.

Morse’s drum faucets are constructed either of polyethylene or metal.

Polyethylene Drum Faucets

Morse makes drum faucets that are constructed entirely from polyethylene. Nonflammable, corrosive liquids are often stored in polyethylene drums, and Morse’s polyethylene drum faucets are perfect for this situation.

These faucets can be opened or closed with just a half turn of the handle. They do not close automatically and will remain open until they are manually closed.

Drums commonly have bungs that are sized for 3/4 inch or two inch National Pipe Thread (NPT). The internal diameters of these bungs are approximately 15/16 inch and 2 1/4 inches, respectively. The two models of drum faucets listed below fit these common bung opening sizes.

Use the smaller sized drum faucet for thin liquids; the larger sized drum faucet is ideal for thick, viscous liquids, or for a higher volume flow of thin liquids.

- Model 68-20 Drum Faucet – This polyethylene drum faucet fits in 2 inch bungs with NPT pipe threads. Its large diameter allows for quick emptying of drums that are filled with thick, viscous liquids. The shipping weight of this faucet is one pound.

- Model 68-75 Drum Faucet – This is also a polyethylene drum faucet. It is sized to fit into the smaller, 3/4 inch NPT pipe thread bung. This is a good drum faucet to choose for drums that are filled with thin liquids. Its shipping weight is 0.1 pound.

Precautions: Polyethylene drum faucets should not be exposed to temperatures higher than 120°F. Do not use them with flammable liquids. Depending upon the situation, other precautions may apply, such as ventilation of the storage area, bonding and grounding the drum, protective clothing, etc.

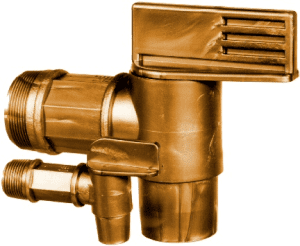

Metal “Molasses Gate” Drum Faucets

These all-metal drum faucets are excellent for use with thick, gummy, slow-flowing fluids – that’s why they are called “molasses gate” drum faucets.

These faucets are very durable, being constructed with a steel handle, a body made from cast gray iron, and a sliding plate made of lapped brass. They are not self-closing – they will stay open until they are manually shut off. The body and the handle have openings that will accept the shaft of a lock, so that the faucet can be padlocked in position.

As with the polyethylene drum faucets described above, the molasses gate drum faucets come in two sizes to fit the two most common bung opening sizes – 2 inch or 3/4 inch National Pipe Thread (NPT).

- Model 65-20 Drum Faucet – This metal drum faucet fits in 2 inch bungs with NPT pipe threads. The shipping weight of this faucet is 4 pounds.

- Model 65-75 Drum Faucet – This metal drum faucet is smaller than Model 65-20 above. It fits into 3/4 inch NPT pipe thread bungs. Its shipping weight is 1.5 pounds.

As an added benefit, all the moving parts of these faucets can be disassembled for cleaning.

Precautions: Do not use these drum faucets with flammable liquids. Other precautions may apply – storage area ventilation, protective clothing, grounding and bonding of the drum, etc.

Drum Faucet Accessories and Customization

Before you can insert the faucet into the drum, you may have to remove the drum plug first. How can you do this? Morse makes drum wrenches for this purpose. These wrenches fit almost any bung plug, and are designed with various surfaces and shapes to fit all the different kinds of bungs used on drums. For durability, they are made of solid ductile iron and constructed in one piece. Spark resistant wrenches are also available, made from manganese bronze or zinc aluminum alloy.

What if the bung on your plastic drum has a buttress thread, which is coarser than NPT threads? Contact Douglas Equipment, and we can supply you with a buttress adapter so you can thread a Morse drum faucet into your plastic drum’s opening.

If you need other modifications for special circumstances, call our customer service representatives and tell us about your requirements. Morse has a large engineering staff and we will work with them to customize a drum faucet built to your specifications.

For More Information, Contact Douglas Equipment Today!

For Morse drum faucets, drum handling equipment, and for all of your material handling needs, contact our customer service representatives at Douglas Equipment today. We have been specializing in material handling equipment since 1955 and have helped customers in all types of industries. Morse makes a broad line of equipment and parts specifically for drums; tell us about your needs, and we will find the exact item you need. Contact us today!