If you need to select casters for use in a bakery, you will face a set of unique requirements not found in other settings. Casters are used everywhere in a bakery. They support the large steel mixing bowls that might hold the dough for 100 loaves of bread, and which need to be rolled from one workstation to the next. Casters support sets of rolling shelves that hold ingredients that go into baked goods, and hold packaged products once they are baked and wrapped.

If you need to select casters for use in a bakery, you will face a set of unique requirements not found in other settings. Casters are used everywhere in a bakery. They support the large steel mixing bowls that might hold the dough for 100 loaves of bread, and which need to be rolled from one workstation to the next. Casters support sets of rolling shelves that hold ingredients that go into baked goods, and hold packaged products once they are baked and wrapped.

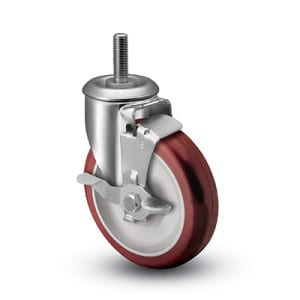

Some casters on bakery equipment never leave the kitchen area. Other casters, for example those on rolling display shelves, might move from the work area out to the retail area, and must look good in front of customers. Brightly polished stainless steel might be a good choice for these casters.

Sanitation is very important in food service operations. Equipment is often subject to harsh cleaning conditions from wash-down sprays, steaming, and the corrosive chemicals found in cleaning agents.

One of the toughest requirements on bakery casters is that they must be able to withstand the high temperatures inside ovens. Bakery racks and shelves are often designed to roll directly into ovens, where they will be subjected to temperatures of hundreds of degrees. Every component of a bakery caster must be designed with these high temperatures in mind – the wheel materials, the treads, bearings, hardware, even the grease used to internally lubricate rollers and bearings must be formulated to stand up to high temperatures.

Extreme heat can affect the lifetime of the caster, its load bearing capacity, and whether or not the equipment that rides on the caster rolls and operates smoothly or not. Choosing the right caster for bakery equipment is an important decision. At Douglas Equipment, we can help you look at all the variables and make the right choice.

Certifications for Food Service Equipment

Sometimes equipment designed for use in food service industries must meet regulatory standards. NSF International certifies commercial food service equipment for regulatory acceptance, as specified by health departments and restaurant buyers in North America and worldwide. You may want to choose bakery casters that carry the NSF logo, indicating that they have met the strict testing and certification standards of this agency.

Let’s look at a few specific examples of high temperature casters that we carry at Douglas Equipment.

High Temperature Bakery Casters from Albion Casters

Douglas Equipment is a distributor for Albion Casters, a company located in Albion, Michigan, which has been in business since 1947. Albion Casters manufactures many lines of casters that can handle the high temperatures found in bakery ovens. Here a few of the bakery casters made by Albion Casters.

- TR Hi-Temp Phenolic – These casters are rated for continuous use up to 475°F, and can handle even higher temperatures on an intermittent basis. They are constructed from a phenolic material, which withstands high temperatures extremely well. The wheel diameter of TR Hi-Temp Phenolic casters is 4 inches, with an overall height of 5 1/8 inches, and a tread width of 1 1/4 inches. They have a load capacity of 350 pounds. These casters carry an NSF certification.

- HE Hi-Temp Nylon – These casters have identical specifications to the TR Hi-Temp Phenolic casters shown above, but they have a tread constructed from nylon. They also carry an NSF certification.

- F4 High Temperature Casters – These are excellent casters for your bakery racks. They are economical, and their soft-tread wheels will protect your floors and roll quietly. They can also handle the heat! They are rated for temperatures up to 480°F intermittent (continuous use up to 285°F). Rubber treads are available in red or black, and are non-marking on floors. Wheels are available made from die cast aluminum (with a load capacity of 170 pounds), or from a high temperature phenolic material (with a load capacity of 185 pounds).

For more information about bakery casters from Albion, please call Douglas Equipment.

High Temperature Bakery Casters from the Colson Caster Corporation

Colson has been in business for more than 125 years. Douglas Equipment distributes Colson casters, and we can help you identify the models suitable for high temperature conditions.

For example, Colson 2 Series Casters are constructed from 304-grade stainless steel, with a polished finish. They can handle corrosive, punishing conditions. All of the component parts are made of stainless steel. These casters are available with many different wheels. Two models in particular are especially well suited for high temperature applications:

- Thermo Wheels – These wheels can operate at temperatures as high as 525° intermittently, or 475° continuously. Colson makes these wheels from an exclusive engineered resin compound. Their life expectancy is three times longer than comparable high temperature phenolic wheels. They have high load capacities, long service life, won’t mark floors, and are 100% recyclable. They are resistant to salt solutions, vegetable oils and animal fats.

- ThermoTECH Wheels – These wheels are constructed with an aluminum core, with a bonded tread made from a rubber compound. This advanced technology compound can handle continuous temperatures as high as 490°F, or 520°F on an intermittent basis. The rubber tread is quiet, can take the heat, is non-marking and will protect your floors.

The load capacity of Colson 2 Series Casters ranges from 150 pounds to 325 pounds, depending on the wheel diameter and tread material selected.

Get Casters That Can Take the Heat – Call Douglas Equipment Today!

For almost 60 years, Douglas equipment has been distributing casters from leading manufacturers around the world. We can help you determine which casters will perform best in your specific environment, so contact us today with your questions!