If you have drums in your warehouse or manufacturing facility you will want to have a safe and efficient way to carry, lift and pour these drums in the easiest way possible. This is where drum carriers can be used to improve your operation. These pieces of equipment are designed to easily lift and pour a 55-gallon drum in a protected, secure manner.

If you have drums in your warehouse or manufacturing facility you will want to have a safe and efficient way to carry, lift and pour these drums in the easiest way possible. This is where drum carriers can be used to improve your operation. These pieces of equipment are designed to easily lift and pour a 55-gallon drum in a protected, secure manner.

If you are looking for information on drum carriers, drum handling equipment or any other material handling equipment to improve your warehouse or manufacturing facility, Douglas Equipment is here to help. We work with the best material handling equipment manufacturers in the business so that we can work with you to find the right piece of equipment to suit your unique needs. When it comes to Morse equipment we are your best first stop.

What is Great about Morse Drum Carriers?

Morse Manufacturing was founded in 1923 and started to produce metal parts and stampings, but quickly moved into the newly expanding automotive field with products for the Model T Ford. In 1943 the company saw a need in American industry to safely and efficiently lift, transport and empty heavy 55-gallon drums and they soon began developing, building and testing new devices that could eliminate the danger and effort needed to work with 55-gallon drums. Since then, they have become a leading manufacturer of drum handling equipment.

Along with drum handling equipment such as drum rollers, drum palletizers and drum handlers and drum tumblers Morse specializes in two types of drum carriers used to lift and pour a drum: forklift-carriers and below-hook carriers.

Forklift Carriers

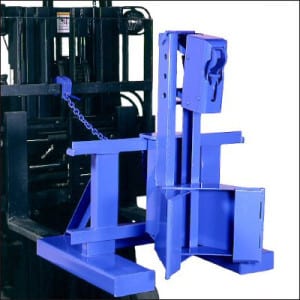

If you have a forklift, then adapting it to handle drums is easy with Morse forklift attachments. These attachments can be used to make the movement of drums safer and easier, and can even be used as dispensing stations when required. Below are two examples of equipment available for these applications:

- MORspeed TM Forklift attachments: These attachments allow for fast handling of rimmed drums with your forklift. You can lift, move and place drums right from the forklift, and the fork mounts in seconds without any tools and no power connections. Massive steel jaws grip under the rim of the drum with a capacity of 1500 pounds per drum, and are available for one and two drum handling. These attachments can handle any diameter drum but require a minimum drum height of 24” and a minimum weight required to activate the jaws of 75 pounds per drum (350 pounds for the two drum head model)

- MORStak TM Forklift Mounted Drum Rackers: To move drums onto and off of racks, pallets and trucks with a forklift, these safety conscious units are the way to go. They allow you to lift a 55-gallon drum in an upright position and then place it horizontally onto a rack or other storage area with zero clearance between the drums. The 2-button control allows you to handle a drum with a faucet attached so that you can utilize the racker as a dispensing station if needed. For safety, the positive drum gripping mechanism must be engaged manually and the MORStak will not allow you to tilt a drum without the clamp engaged. The racker can handle steel or plastic drums of up to 800 pounds.

Below-hook Carriers

Designed to lift and pour a drum using an existing crane lift, these units are ideal for this application. The below-hook carriers come in manual and power tilt options, and fit on any overhead crane unit that you may have. Manual tilt units utilize chains and pulleys to control the tilt of the drum and are available for drum weights from 800 pounds to 2500 pounds. Power tilt lifts are also available.

- Model 185A-HD Heavy-Duty Kontrol-Karrier: The Kontrol-Karrier can lift, move and control the pouring of heavy drums when attached to your crane hoist. This unit can handle drums up to 1500 pounds and provides a fine tilt control with a 60:1 ratio gear and sprocket drive. The MORcinch TM drum handling system includes options for handling steel drums, plastic drums, fiber drums or various smaller sizes than the standard 55-gallon drum. Safety options include spark resistant parts for drums containing flammable materials and the MORStop tilt-brake to add automatic hold of the drum at the tilt angle for easy pouring.

- Power-Tilt Kontrol-Karrier: This item adds the ease of power controlled drum rotation to your crane mounted drum carrier. The power tilt unit can rotate a drum 360 degrees in either direction and allows for you to fully invert a drum in 15 seconds. The unit is operated with a 2-button control pendant of hand-held control valve as desired. The basic model can handle 55-gallon steel drums up to 1500 pounds and has optional attachments for plastic drums, fiber drums and diameter adaptors for smaller sized drums.

Douglas Equipment: Your Best Place to get Morse Drum Carriers

Douglas Equipment has been in the business of quality casters and material handling equipment since 1955, and in our almost 60 years we have strived to gather the best material handling equipment available for the tasks you need. Our dedicated service team is trained to help you with any questions you may have when it comes to picking out the right drum carrier for your unique needs.

We are located in Miami, which means we can easily service the entire United States, South America and the Caribbean. Contact us today for assistance choosing drum handling equipment.