There are many types of casters that you can use for a multitude of applications. Which casters are best depends upon what you are going to use them for. If you’re going to use them to transport slow, heavy loads, then certain casters are better than others. If, however, you’re going to use them to transport loads at high speeds, then you’re going to want a certain kind of caster. The last thing you need is a caster that will fall apart under pressure, or will constantly jam as your load.

There are many types of casters that you can use for a multitude of applications. Which casters are best depends upon what you are going to use them for. If you’re going to use them to transport slow, heavy loads, then certain casters are better than others. If, however, you’re going to use them to transport loads at high speeds, then you’re going to want a certain kind of caster. The last thing you need is a caster that will fall apart under pressure, or will constantly jam as your load.

Making the right choice is important. You want your business to run as smoothly as possible, and that means all the individual elements of your business will need to run smoothly too. Having a bottle-neck because the casters you have chosen are not up to the job will affect your entire operation as a whole, and will reduce your company’s efficiency.

Here are a few notes about the most common types of casters you may find on the market, and their suitability to be used to transport loads at high speeds.

Cast Iron Wheels

Casters that are made from cast iron are extremely durable and long-lasting. They’re resistant to shock and are a good choice when it comes to heavy loads. They can also withstand exposure to water, chemicals, grease and oil, plus they can withstand high temperatures.

Cast iron wheels will rust over time. They’ll work well in high-speed environments, but running them at speed will mean they’ll need replacing quite quickly. Cast iron wheels are a decent choice, but there are better options.

Phenolic Wheels

Phenolic wheels are manufactured from macerated cotton canvas that has been mixed with phenolic resin. They’re molded using high-pressure molding, which means they have maximum density, and can boast super strength. They roll very easily, they’re not as loud as metallic wheels, and they won’t damage floors.

However, Phenolic wheels are not suitable for high-speed environments – they’re more suitable to high-temperature environments, like bakeries. They should not be used on uneven, or damaged floors either.

High-Tensile Rubber Wheels

These are molded rubber wheels that are rated as being twice as effective as normal molded rubber wheels. They’re highly durable and resistant to cracking. They can be used in both interior and exterior environments. High-tensile rubber wheels will not damage your floor; they’re noise-free and can easily tackle debris.

They’re also an effective choice when it comes to high-speed usage, especially for large-scale assembly plants and freight terminals. A good, all-round choice.

Hard Rubber Wheels

If your available budget is an issue, then a hard rubber wheel is something you might consider. These are low in cost and provide easy rolling where necessary. They won’t damage floors unless the floors are too soft, and are less noisy than metallic wheels. They’re easily damaged too.

Hard rubber wheels are perhaps not the best choice when it comes to high-speed environments. They’re not resilient, and will probably need to be replaced on a regular basis.

High-Temperature Glass-filled Nylon Wheels

These casters are molded from reinforced nylon, and they’re specially designed to cope with high temperatures and high-pressure environments. They can handle heavy loads, and can cope with water, oils, fats, petroleum, solvents, cleaning solutions, acids and salt.

Again, these wheels are more suited to high-temperature environments. If you’re looking for high-speed casters in normal temperature environments, then there are even better choices to make!

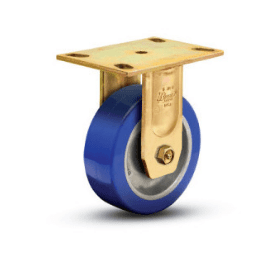

Polyurethane Wheels

Polyurethane is a polymer which is built to contain high-strength carbamate links. These wheels are flexible but durable enough to maintain their shape, even after a high-speed impact. They’re resistant to damage, and are less nosy than metallic wheels.

As a material, polyurethane is an excellent choice when it comes to casters designed to carry heavy loads at high speeds. This is one of your most appropriate choices if you operate in a high-speed environment.

Pneumatic Wheels

Casters made using these wheels are ideal if floor protection is an issue. They glide freely over both obstacles and damaged flooring. If you have delicate materials to transport, then these wheels are an excellent choice. They can be used for commercial, industrial or institutional applications where safe transport and comfort is a must.

However, the downside of pneumatic wheels is that they can be punctured. This means that they cannot be used for high-speed applications where there is a danger of this happening.

Stainless Steel Wheels

Such wheels are ideal for highly-corrosive environments. They can also be used where they’re likely to be subjected to high temperatures. Typically, such wheels are used in food preparation plans, chemical plants and medical applications.

Generally, such wheels are not suitable for high-speed applications.

Polyolefin Wheels

These wheels are another budget saver. Polyolefin itself is an extremely durable plastic, which offers superior resistance to both water and chemicals. They’re also effective at withstanding impacts, and are more resistant to abrasion than rubber wheels. Such wheels can be used in bakeries, meat preparation plants, laundries, supermarkets and offices.

They would be a moderately successful choice if you choose to use them for high-speed applications, especially of you’re on a limited budget. They’re quite maneuverable, and you can order them in a variety of sizes. You should have no problem finding a size that’s suitable for your specific application.

When it comes to casters, your choices can be somewhat baffling. If you’ve never ordered casters before, then you may be confused by all of the options available to you. To this end, it’s often a good idea to speak to someone who has experience in material handling equipment.

At Douglas Equipment Company, we would be happy to help you navigate your way through the difficult process of choosing casters that support high-speed usage.Feel free to reach out to our team anytime, by calling 800-451-0030, or through our contact form.