What should we expect from casters? When they function perfectly, we may not even know they are there – and this can be a good thing! If a caster does not draw attention to itself, that probably means it was properly selected for the work that it must do; that it’s in good shape; and that it’s doing the job it was meant to do, and doing it well!

What should we expect from casters? When they function perfectly, we may not even know they are there – and this can be a good thing! If a caster does not draw attention to itself, that probably means it was properly selected for the work that it must do; that it’s in good shape; and that it’s doing the job it was meant to do, and doing it well!

If a caster catches your attention, is it because you’re thinking, Wow! I can’t believe how well this piece of equipment is rolling! Maybe your thoughts are: This caster is ruining my day!

If you chose the second answer, then read on – we hope to give you some information that may help you improve the performance of your casters.

Casters That Are Wrong – Right from the Start

Some casters work well at the beginning of their life cycle, and fail later on. Others perform poorly, right from the start. In this section, we’ll discuss some of the ways that casters seem to malfunction early on. Most of these problems can be due to casters that were selected for the wrong reasons, or used in the wrong applications.

- Noisy Casters – Casters that make too much noise can be a tremendous irritant to those who are exposed to the noise. Sometimes the noise is inevitable; the caster must be made from a certain material in order to stand up to the conditions under which it is used. However, the designer who specified the wheel material may have simply neglected to choose one that was quiet. For example, polyolefin wheels stand up well to shock and impact loads – but are very noisy. Other wheel materials, such as polyurethane, can often be specified just as easily, but with much quieter results.

- Casters That Ruin Floors – If the casters on your equipment were not chosen with floor protection in mind, they can wreak havoc on the flooring in your facility. If floor protection is important to you, make sure you specify casters that will be well matched with your flooring.

- Casters That Are Too Small – The larger the diameter of casters, the easier it is to get them rolling. Smaller casters require a greater force to initiate movement. This can tire out workers who must push rolling equipment all day long. Another benefit of larger casters is that they will roll more easily over cracks or obstacles.

- Casters That Are Too Big – Casters that are too large in diameter may raise the center of gravity of the equipment, making it unstable. Because they roll more easily, large casters may be a poor match for equipment, such as hospital carts, that must be parked and stay in one position. For stability, smaller casters are sometimes the better choice.

- Casters Not Well Matched with Environmental Conditions – The designer of a piece of equipment should take into account the environmental conditions and choose casters appropriately. Oil and grease, water or steam, and extreme heat or cold can quickly take a toll on casters not designed to stand up to those particular conditions.

Whether you are replacing casters that have been ruining your workday, or selecting casters for a new piece of equipment, a little bit of time spent on picking the right casters for your particular conditions will go a long way toward helping your casters function well.

Casters That Work Well from the Start – But Then Go Wrong

Unlike the problems discussed in the previous section, most of which occurs early on, other problems with casters take time to develop. If you have casters that worked well in the past, but are now having a negative impact on your workday, then look for possible solutions in the following list.

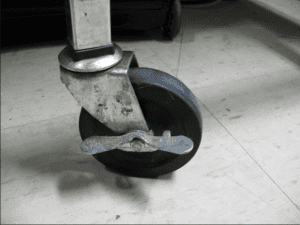

- Shimmying Casters – If a caster is not in full contact with the floor, it may start vibrating rapidly from side to side. This “shimmying” can be due to a bent caster. Make sure to choose casters that are properly specified for the loads they must bear – this can help prevent bent parts.

- Flat Spots on Wheels – Casters can develop flat spots on their wheels, which make them difficult to get rolling. Once in motion, the flat spots can cause vibrations that jar the load. A number of factors can cause these flat spots. These include loading the caster beyond its rated specifications; parking the piece of equipment in the wrong environment; and even exceeding the rated speed of the caster—all can cause some wheel materials to overheat, then deform while at rest.

- Casters That Stop Rolling or Swiveling – Many casters depend upon bearings that allow the wheel axles to turn, and swivel sections to rotate. Some of these casters require lubrication; others do not. Debris can enter between moving parts, and compromise bearing rotation. For lubricated casters, the lubrication must match the environmental conditions. For example, in high heat applications, make sure to choose casters whose lubrication material has been formulated to stand up to high temperatures. To keep debris from causing problems, sealed bearings are often specified.

Casters that worked for a time, but then malfunctioned, may give you a clue as to what went wrong. Use any clues available, along with the information above to help you choose replacement casters that will perform better, and for a longer period of time.

For Casters That Function Perfectly – Contact Douglas Equipment!

The first step in correcting problems with malfunctioning casters is to notice that you are not satisfied with their performance. For help in determining what’s causing the problem, and how to pick the right replacement casters, contact one of the experts in our customer service department. We can quickly help solve your caster problem, so that you can get your equipment functioning more smoothly – and for a long time! Please call us today at 800-451-0030, or 305-888-3700 in the Miami area. You can also fill out our contact form. We look forward to hearing from you!