Does your company deal with the distribution of drums? Do you work at a dock, or do you store your drums and freight in some type of warehouse facility? If so, you’re going to need some type of drum handling equipment for the loading and unloading as well as the transportation of the drums within your facility.

You should never compromise on the quality of your drum-handling equipment. Doing so will make the jobs of your employees just a little bit more difficult and could even compromise their safety. Here are some examples of what our team at Douglas Equipment thinks are the best items of drum handling equipment that we can provide for you.

Top Drum Handling Equipment for Docks, Freights & Warehouses

Morse Drum Rackers

If your business involves the movement of drums, then you likely need somewhere to store them when they are not being moved. Specialty shelving assemblies are used for the horizontal storage of drums. Normal racking is not suitable as the drums would simply roll around and become difficult to manage. For these challenging environments, you’ll need a drum racker, a tool for the placement of the drums upon the racking.

Morse manufactures two types of drum racker – the Omni-Lift Drum Racker and the MORStak Drum Racker. The Omni-Lift version is a battery, A/C or air-powered lifter capable of raising drums up to six feet. The MORSrak version is the same aside from it can lift drums even higher. Both models are designed for use with standard 55-gallon drums, although can cope will alternative drum capacities as well.

Watch this video demonstration on how a MORStak Drum Racker works:

Wesco Fork Drum Grabs

Within your facility, it’s probable that you already own a fleet of forklift trucks. If so,there really is no point in splashing out extra cash to purchase specialist forklifts for use in handling drums.With a fork drum grab, as manufactured by Wesco, you can temporarily ‘convert’ a ‘normal’ forklift into one suitable for handling drums. There are a number of different models available, but they all basically work in the same way. The grab is fixed onto the forks of any suitable forklift truck to allow it to become suitable to handle as many drums as you desire.

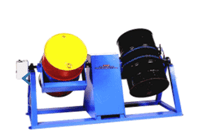

Morse Drum Tumblers

One of the main issues with drums is that over time, their contents can settle or separate if they are stored for long periods. If you’re supplying companies with drum-contained products you’ll want them to arrive at your customer’s locations in the best condition possible.

You can easily mix the contents of any drum using a drum tumbler. These devices – such as Morse’s End-Over-End Drum Tumbler – can be left for a perid of time to complete the mixing process. The drum is simply rotated with constant motion for as long as you see fit, until the contents of the drum are once again, fit for purpose.

Douglas Equipment is happy to talk to you regarding the purchase of any of the items mentioned in this article, or just for some general information or advice. You can contact our team via phone at 1-800-451-0030 or via email through our online contact form.