It may seem easy to order casters. All you have to do is browse through some websites or catalog pages, find a model that seems close to your needs, and place an order. What’s not so obvious in this process however, is that oftentimes the first caster you see is simply the basic, standard version of that model.

It may seem easy to order casters. All you have to do is browse through some websites or catalog pages, find a model that seems close to your needs, and place an order. What’s not so obvious in this process however, is that oftentimes the first caster you see is simply the basic, standard version of that model.

In their webpages or data sheets, manufacturers often present their basic version of a caster first – with the idea that this is only a starting point of options for you. Each caster model may have dozens of different options available; after you’ve chosen different combinations of options, it may be possible to come up with thousands of different variations on that initial caster you first looked at.

The first step in ordering a caster is knowing that these dozens of options and thousands of variations exist. Armed with this knowledge, you will be able to specify a caster that’s perfectly matched to your application – rather than settling for the standard model, which may come close in many ways, but miss the mark when it comes to other important features.

Let’s Order a Caster! – A Colson Example

Douglas Equipment is an authorized representative for the leading caster manufacturers in North America as well as internationally. We have more than a dozen manufacturers listed on our website, and have relationships with other manufacturers, too.

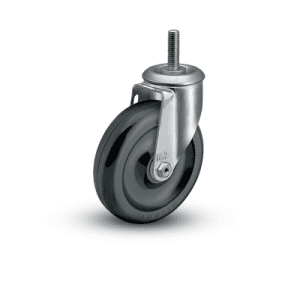

As an example of little changes making big differences with your casters, we’ll choose one manufacturer – Colson Casters – and go through the process of exploring some of the options available as we configure a typical caster: a swivel caster with a top plate mounting.

For our example caster, let’s look at Colson’s 2 Series casters, which have 1 ¼” tread width, and are rated for loads up to 325 lbs. We see that seven different mounting options are listed, with top plate casters available in zinc-plated or stainless steel finishes. Let’s choose zinc plated swivel casters.

Little Changes That’ll Make a Big Difference – Exploring the Options

As we look at the table of specifications, we see that we have a wonderful variety of options to choose from, enabling us to configure the exact caster we need.

Mounting Plate – This is available in four different sizes. The mounting plate helps in choosing a plate that can be precisely matched with the structure to which it will be mounted.

Wheel Diameter – Wheels are available in five diameters. Larger wheels are rated for higher load capacities. At the smallest size, 2 ½” wheels are rated for 140 lbs.; at the largest, 5” wheels are rated for 325 lbs. 3”, 3 ½” and 4” wheels have capacities lying between.

Being able to pick different wheel diameters allows you to do more than just pick a caster that will support your intended load. It also allows you to determine how easily that load will roll, and how stable it is. Larger diameter wheels will roll more easily. Smaller diameter wheels will lower the center of gravity of the load, which helps make it more stable.

Wheel Type – Up to nine different types of wheels are available. Choosing a wheel type and tread is one of the most critical decisions to make when picking a caster. Each one has been designed for specific situations. Choosing the right wheel type will help ensure your caster works perfectly, with a long life span. Some of the options for 2 Series casters are:

- Performa – These wheels have characteristics of both hard and soft tread materials. They are very durable and roll easily, yet are quiet, protect floors, resist impacts and offer a cushioned ride. They stand up well to weather, chemicals, water and steam, and reject debris (such as metal shavings).

- Performa Conductive – These wheels have the characteristics of Performa wheels listed above, and also meet federal specifications that require an average electrical resistance of less than 250,000 ohms.

- Polyolefin – These wheels can take heavy loads and hard impacts. They are resistant to most oils, grease, chemicals, acids and cooking fats. They are non-marking and do not absorb water.

- Thermo – These wheels are rated to operate from temperatures of -70°F to +525°F intermittent service, or 480°F continuous service. They are molded from an engineered resin compound, and are superior in many ways to high-temp phenolic wheels.

- ThermoTech – The rubber tread on these wheels can take the heat. It’s an advanced technology rubber compound, which is bonded to an aluminum core. They don’t mark floors, and are quiet.

- Polyurethane Hi-Tech – The polyurethane tread of these wheels is molded around and through a ribbed extension of the polyolefin core; this prevents de-bonding. These wheels are resistant to solvents, chemicals, acids and water.

- Cast Iron – Use these wheels if your casters must support excessive load weight. Cast iron wheels should not be used if floor protection or noise is a concern.

- Rubber HI-TECH – These wheels are made from a thermoplastic cushion rubber tread, which is bonded to a rugged polyolefin core. They are rated for load capacities up to 150 pounds each.

- Phenolic – Made from phenolic resin filled with macerated fabric, these wheels are quieter than steel or aluminum, resist hard impacts, and offer superior floor protection. They are resistant to steam and most chemicals.

Take advantage of wheel options, and order a caster that will be exactly matched to the conditions under which you will use it.

Even More Options! – as you delve deeper, you’ll find even more options. You can choose one of three different brakes: top lock, total lock, or directional lock brakes. Delrin, Teflon or ball bearings are available on some configurations. Zerk axles, dust caps, thread guards, and NSF listed models offer even more choices!

Let’s Talk about Options – Contact Douglas Equipment!

Every caster has dozens of options available – but it’s not always easy to find the ones you want. If you contact one of the experts in our customer service department, we’ll be happy to recommend little changes that will make a huge difference with your casters. Contact us at 800-451-0030, or 305-888-3700 in the Miami area. You can also reach us through our contact form.