The range of environments where casters are used is truly astounding. At Douglas Equipment, we help our customers choose casters that can be used anywhere – from kindergarten classrooms or posh hotel lobbies, to gritty, dirty and loud steel mills or automobile production plants.

The range of environments where casters are used is truly astounding. At Douglas Equipment, we help our customers choose casters that can be used anywhere – from kindergarten classrooms or posh hotel lobbies, to gritty, dirty and loud steel mills or automobile production plants.

For heavy industrial environments, unique problems arise that are never found in the less demanding environments.

When the Going Gets Tough

To help understand the demands that casters face in a heavy industry, we’ll start by examining one of the simplest pieces of material handling equipment – the cart – and learn about challenges that its casters must help solve. Then we’ll consider more complex equipment, and additional challenges they face.

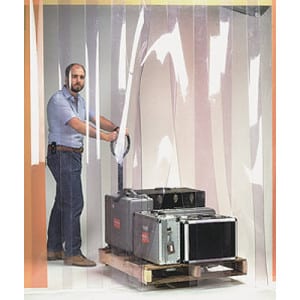

Raw materials are often moved to the production line on carts; partially completed assemblies are transferred from the line to carts, to be rolled to the next assembly station; and finished products are sometimes loaded onto carts and moved to the shipping area. Whether these carts are pushed by hand, or linked together in trains of four or five, and pulled with power-aided equipment, they all depend on the right type of caster for proper functioning.

- Push Force – A well-designed caster can reduce the push force required to set the cart in motion. If the push force is too great, two workers might be required to start the cart rolling. Low friction casters can reduce the push force, allowing one worker to move the cart, from start to finish. Chances of worker injury are reduced as the push force is lowered.

- Debris Accumulation – If the cart wheels pick up and accumulate debris from the floor, the cart can become difficult to push and steer. Debris can cause the wheel or tire material to go out of round, also increasing the push force required. Choosing the right wheel material can greatly reduce these problems.

- Steering – As loads increase to thousands of pounds, proper steering of the cart can become an issue. This issue can be compounded when several carts are hooked together, and pulled along in a train. Ideally, all of the linked carts should follow the same track. Casters are available that will help make the steering of the cart effortless and accurate.

- Noise Reduction – Industrial environments can be noisy places. To reduce noise and protect workers’ hearing, many companies will examine every piece of equipment used, and try to find ways to reduce the noise. By choosing the right casters and wheels, formerly noisy carts can be made to roll smoothly and quietly across the factory floor.

When we look at industrial equipment that’s more complex than carts, we find that many of the problems mentioned above are also important with the more complex equipment, and that some new problems are introduced.

Automatic Guided Vehicles (AGVs) – These are carts that are self-powered, and steered automatically under computer control. Depending on the industry, the load placed on an AGV can be quite heavy. Reducing push force is important, because it can lead to increased battery life, and higher speed operation.

In highly automated facilities, positional accuracy of the AGV can be very important. The AGV may need to precisely line up with an automated machine, for material transfer or machining operations. If wobble in the casters could throw off this alignment, then it becomes important to choose casters that will eliminate wobble.

Conveyor Systems – These are prevalent in the heavy lifting material industry. They move small parts, but also items as large as an entire automobile or railroad car. One of the key considerations in selecting casters and wheels for conveyor systems is that they must be low maintenance. If a conveyor line stops because of a caster failure, the down time can be very expensive. Therefore, casters should be specified that stand up well to the demands of the conveyor system.

To stand up to heavy loads, casters must solve the problems discussed above, and sometimes other unique challenges as well. When choosing a caster for a heavy load, what should you consider? We’ll talk about that next.

Help for Specifying Heavy Duty Casters

As loads increase, or for tough industrial environments, here are a few things to help you make a good choice when selecting the right caster.

- Go from Single to Dual Wheel Casters – Using two wheels rather than one will improve load distribution by spreading the load out over a bigger area on the floor. Dual wheel casters have a lower height than other heavy-duty casters, which can be important in some applications. Dual wheel casters will last longer than single wheel casters. This can help with maintenance costs.

- Add Shock Absorbing Springs – Sometimes cushioning is important with heavy loads. Heavy-duty casters are available that are made with shock absorbing springs, which cushion the load. The springs can increase load capacity, reduce vibrations and shimmying, and reduce noise while in motion.

- Pick the Right Kingpin Style – The maximum capacity and type of load can help determine the style of kingpin you choose. For constant swiveling with large loads, kingpin casters with precision load bearings and slotted adjusting can improve strength and caster lifetime. Casters built with super heavy duty kingpins increase load capacity even more.

- Eliminate the Kingpin Altogether – Casters that are built without kingpins can also withstand heavy loads. With no kingpin, the swivel section can rotate more easily, and the caster’s useful life is increased. Eliminating the kingpin can also result in lower prices.

Call Douglas Equipment – We’ll Help Lighten Your Load!

Searching for casters that have to stand up to extreme industrial conditions, or deal with height constraints, gritty floors, and high maintenance costs can seem overwhelming! But don’t despair! Call the experienced team of support representatives at Douglas Equipment, where our experts will help you find the perfect caster. We can be reached at 800-451-0030, or online. In Miami, our local number is 305-888-3700. We look forward to hearing from you!