If your company’s processes and procedures involve running a warehouse or any kind of storage facility, then you probably own an electric pallet jack or two. These versatile little beasts may also be called pallet lifters or pallet stackers, and they are used to easily lift pallet-laden items and move them from where they are stored to where they need to go.

If your company’s processes and procedures involve running a warehouse or any kind of storage facility, then you probably own an electric pallet jack or two. These versatile little beasts may also be called pallet lifters or pallet stackers, and they are used to easily lift pallet-laden items and move them from where they are stored to where they need to go.

They are mainly used for less-strenuous tasks that do not require the use of a forklift truck. Most warehouse-based companies – such as wholesalers – typically own both forklift trucks and pallet jacks. The fork lifts handle the heavy-duty items, while the pallet-jacks are used by the workforce for item-by-item shifting. Forklifts are usually employed for loading and unloading trucks, and for raising pallets to higher levels of storage shelving. Pallet jacks are used for shifting ground-level pallets from storage to where they need to be relocated.

What are the Benefits of Using an Electric Pallet Jack?

The main benefit of an electric pallet jack is the function of covering a wide range of distances at greater speeds and in shorter expanses of time than with a manual jack. Pallet jacks are particularly useful in large-scale warehouses where the motorized aspect allows the driver to ride upon the jack as they are moving their loads. Because an electric pallet jack is more efficient than a manual one, the level of a worker’s efficiency obviously increases.

Even less powerful electric pallet jacks are useful in commercial enterprises that do not have large-scale warehouse facilities. Typically, an electric pallet jack is much smaller than a forklift, resulting in easier maneuverability. This means the operator is able to ride effectively through the warehouse facility, which in turns means they are able to pick up smaller orders more quickly.

Other Benefits of Using an Electric Pallet Jack

Typically, forklift trucks handle most of the heavy-lifting tasks in a warehouse facility, but an investment in electric pallet jacks can be a cost-effective addition to your entire fleet. Small-to-medium sized businesses will make use of electric pallet jacks in order to move smaller pallets to docking areas to and from storage areas and from the warehouse to retail areas if your company has a retail component. Pallet jacks can also be used in other ways – like being loaded with boxes for transportation or moving large items of furniture. Whatever pallet jacks are used for, they are exceptionally versatile.

Like forklifts, electric pallet jacks are typically battery-powered using rechargeable battery packs. However, unlike forklifts, electric pallet jacks are much lighter. They use less power and they are quicker to charge. An electric pallet jack can always be held on ‘stand by’ in case a forklift unexpectedly runs out of charge. While an electric pallet jack cannot be expected to perform ALL the functions of a forklift, it’s better than having nothing at all.

Why Invest in Forklifts or Manual Pallet Jacks?

Some forklifts are gas-powered. While this is effective in large-scale open environments, it’s not wise to invest in such forklifts in smaller areas because of gas fumes. Electric pallet jacks are a much safer alternative for smaller warehouses. They also have tighter turning circles than forklifts. This makes them better to use in areas where the shelving is positioned so that it is close together.

One additional feature that’s likely to be of use is that the electrified factor of an electric pallet jack means the raising and lowering of pallets is powered. With a manual pallet jack there exists the necessity to use the hydraulic pump in order to lift pallet items from ground level so they can be transported. While hydraulic systems are very efficient and the pumping action requires only a slight amount of operator effort, the electrified action of a motorized pallet jack saves both effort and time.

What Industries Utilize Electric Pallet Jacks?

Some industries that use electric pallet jacks include:

- Automotive

- Food and beverage

- Iron and steel manufacturers

- Largescale retailers

- Logistic centers

- Manufacturers

- Paper manufacturers and retailers

- Ports

- Steel plants

- Lumber companies

Which Companies Make the Best Electric Pallet Jacks?

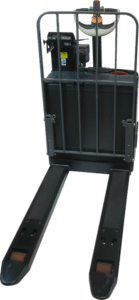

For an all-round, all-purpose electric pallet jack, our team at Douglas Equipment recommends the Heavy-Duty Electric Pallet Truck manufactured by our good friends at Wesco. This versatile piece of equipment is constructed of solid American-made steel and has a loading capacity of 3,300 lbs. – more than enough to cope with the demands of most warehouse facilities.

It has a width of 33”, and a depth of 47”, making it much more compact than a sizable forklift. The load-bearing wheels are constructed from moldon polyurethane for reliability and smooth rolling.

Important Features about Pallet Jacks

The electric, battery-powered pump comes complete with charger and the unit even features a one-year pump warranty. Please note that the battery is only used to drive the unit, not to raise the forks. There are no ‘ride on’ abilities for this model – for safe and secure operation it is recommended that the operator walk behind the unit as opposed to riding on it. Fork raising is performed by manual pumping of the handle. The unit has a speed of just less than 3 miles per hour when under load, and the entire electric pallet truck has a 62-degree turning radius. The whole unit weighs 452 lbs.

What Other Kind of Material Handling Equipment Does Wesco Offer?

Wesco makes a wide range of electric pallet jack trucks of all shapes, sizes and capacities. Whatever solution you are seeking to provide, we are sure that there is a Wesco manufactured product that will perfectly suit your needs and your budget.

Please feel free to contact us at any time. We can supply you with an excellent range of material handling equipment from many of the top manufacturers worldwide. We also provide a superb range of casters suitable for multiple applications.

To speak to a member of Douglas Equipment’s’ expert sales team, all you need to do is call us at 1-888-982-9078 or reach out to us through our online contact form.