An Alternative to the Forklift

An Alternative to the Forklift

If your business needs to transport items frequently, a good option to consider in terms of moving equipment is a powered stacker. A powered stacker offers a hybrid mix of power and convenience. A powered stacker allows an individual worker to mobilize the device and maneuver accordingly. It is a good alternative to a forklift in pedestrian-busy spaces or in work spaces in which space is already at a premium. Due to the size of most powered stackers, they can be maneuvered around tight corners and move through busy spaces at a quicker pace than when utilizing other moving equipment such as the traditional forklift. Also, with a powered stacker, a worker can move large amounts of items quickly and efficiently without physical strain, which reduces the risk of injury.

Many Potential Uses

There are many areas in which a powered stacker can be utilized. A powered stacker is very useful in a warehouse where items may need to be moved from section to section, but also moved up and down depending on shelf placement. They can be utilized in loading docks where it makes moving items up to the dock an easy task. Powered stackers can even be utilized in retail areas, moving new inventory to the appropriate place for merchandising. Powered stackers can also be utilized in factories to speed up movement of items from section to section. These are just the beginning of the work spaces in which a powered stacker may be useful.

A Variety of Options

Just as with almost everything in today’s world, when it comes to stackers, there is a large variety of types available. Depending on the items that need to be moved, the type of space in which the items will be moved, there is a powered stacker that will be the best fit. A few examples of the kinds of stackers available include: counter balance power lift stackers, platform model power lift stackers, fork model power lift stackers, adjustable span straddle power lift stackers, telescoping power stackers and power stackers specifically designed to accommodate very heavy loads.

Individual Attributes for the Best Fit

Each type of power lift stacker has certain attributes that allow it to be useful in certain ways. Therefore, it is very important to be familiar with the types of options available in order to make the most informed decision when purchasing one. For example, the counter balance power lift requires that the load be counter balanced, so it is important to know in advance the weight of the load to be lifted in order to have the correct number of weights to counter balance. The platform model power stacker offers a solid platform on which to lift items, which can be useful when moving multiple small items that may not be easily balanced on another type of stacker. The adjustable span straddle power lift stacker is exactly as its name indicates. Its straddle legs can be adjusted to fit most standard sized pallets. Another special option is the telescoping power lift stacker, which is designed to lift loads higher than the standard lifts making it easier to move things to higher places more easily.

Specific Qualities

When trying to decide the best option for your constantly moving business it is helpful to enlist the guidance of a trusted supplier. Douglas Equipment has more than fifty years of experience in the moving equipment business. We pride ourselves in not only a full knowledge of the industries’ options, but we also maintain the importance of the responsibility to offer machines, equipment and tools to our customers that reflect our standards of quality. One of these manufacturers is Wesco. Wesco produces an large variety of power stackers and have one of the most trusted names in the business. Of the power stackers they offer, each of them have further individual characteristics that pinpoint its purpose and best use. With the differing types of stackers available they each come with individual characteristics that are beneficial to the job they are designed for. Some of the different attributes that may be found on the varying power stackers include the following:

Basic Power Stackers

• Variable speed, steerable power drive system allows a single user to easily control forward and reverse movement of stacker

• Simple to use finger-tip controls are built into steering handle

• 180-degree hinged design allows precision steering in confined spaces.

• Red emergency stop button

• Spring-loaded mechanism automatically compensates for uneven floors ensuring drive wheels maintain constant contact with floor.

• Automatic emergency safety switch instantly reverses direction if control post comes in contact with obstacle.

• All other operating specifications are the same as equivalent power lift-only models

• Two maintenance-free sealed batteries provide plenty of power for propulsion and lift.

1,000 – 2,000 lb capacities

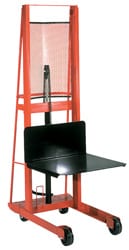

Platform Model Power Stacker

• 24″ x 24″ to 30″ x 32″ platform size

• 5″ phenolic wheels on front, 4″ phenolic swivel casters on rear

Telescoping Power Stackers

• Instant carriage stop for accuracy – no drifting

• Adjustable forks

• Heavy duty rigid frame and base

• High strength mast for increased stability

• Double chain lift for better balance and load support

• Heavy-duty pump

• Ergonomic “D” handles

• Optional 5th wheel for easier overall mobility and turning in confined areas

Adjustable Power Stackers

• Extra deep (40″) straddle legs and forks for lifting pallets

• Versatile adjustable span straddle legs can be set from 34″ to 50″ inside dimension to handle most standard pallets

It can be a difficult decision to decide which piece of equipment is the one best suited for your business. Douglas Equipment is a trusted source for finding the right power stacker for your business. We have been in business since 1955, and are always striving and excited to offer you the best service, the most economic prices and the trusted advice that you can rely on. Please contact us for more information on finding the most-economical and appropriate power stacker from Wesco. Please contact us Toll-free at 1-800-481-0030 or you can reach us by contacting us through the Contact Us section on our website. We look forward to working with you.